ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more-

Extended Wipe Down Arms

Extended wipe down arms for complete wipe down from start to end, providing the complete product protection.

-

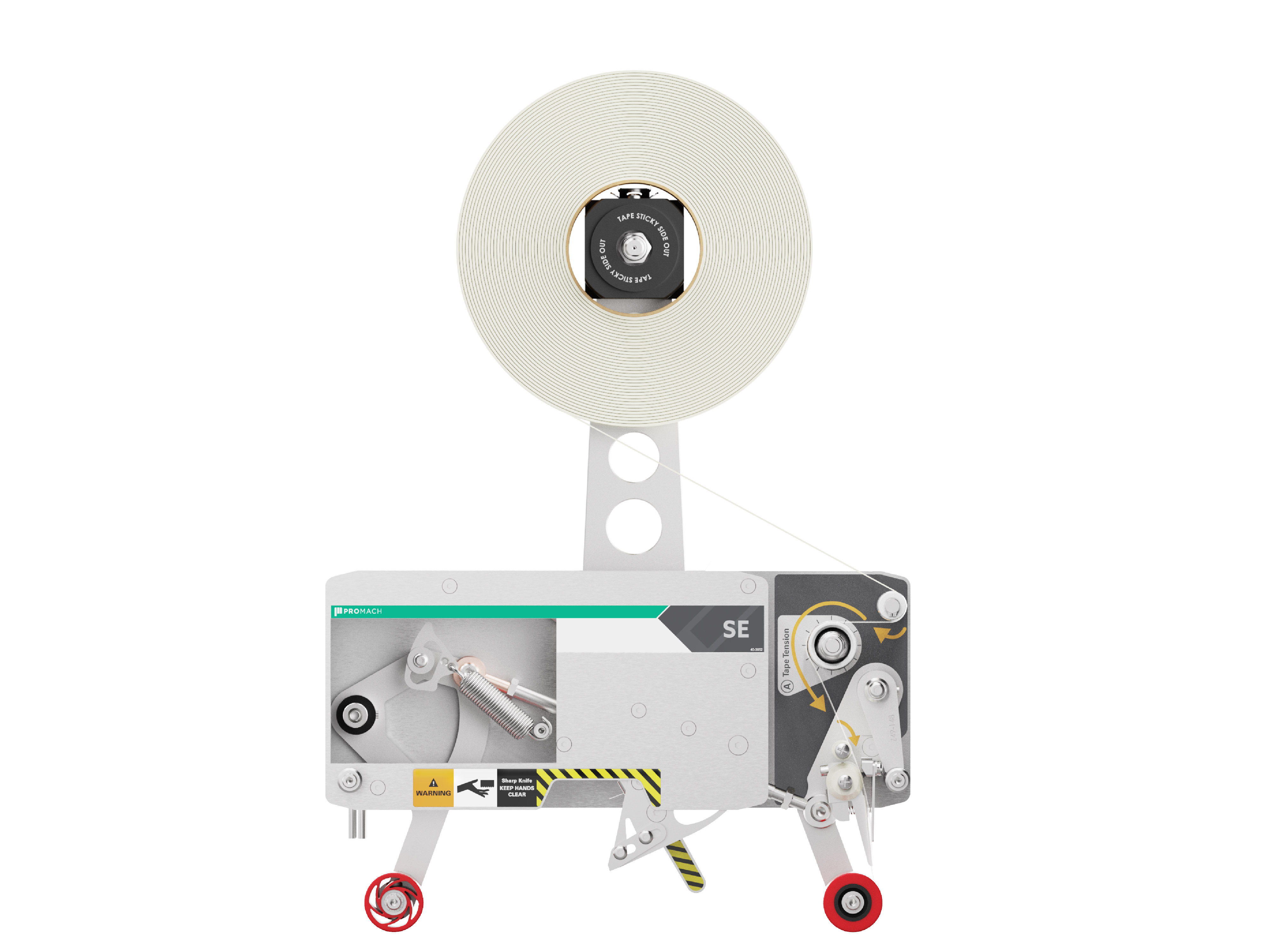

Tool-less Tension Change

Wipe down tension can be easily changed without the need for tools, allowing for quick adjustments and optimization when variations in tape or corrugated appear.

-

Stronger, Faster, Deeper Cut

Overhauled cutting mechanism for superior performance in under-fill or recycled corrugated applications. The improved cutting distance also improves compliance on case sealers which are inaccurately adjusted.

-

Adjustable Wipe Down Brush

An adjustable brush with stiff bristles provides evenly distributed wipe down pressure across the entire tape surface. The brush is adjustable to allow for better angles which may suit different applications better.

-

Labelled Adjustments

On-machine labels identifying common adjustment points and common spare parts for easy machine operation and maintenance.

-

10 Second Tape Threading

An open side frame design along with on-machine pictorial guides for quick tape threading in 10 seconds

-

Patented No-Break Tape Advance

The DEKKA SE pulls along the center-line of the tape roll to avoid putting stress on the edges which is where most tape breakages occur.

-

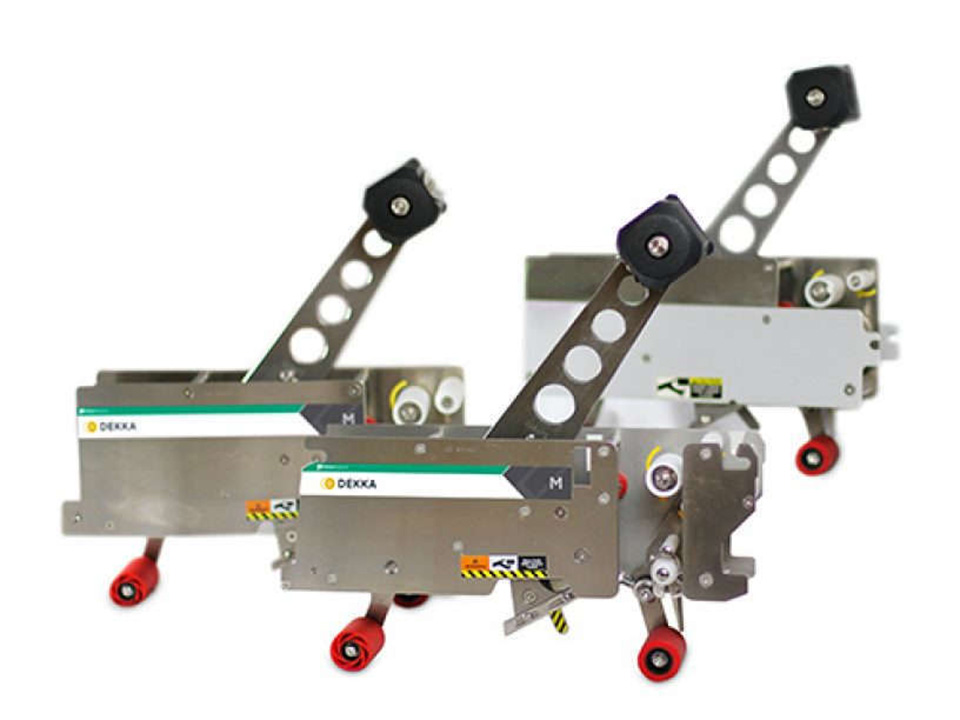

Quality Construction

High quality corrosion resistant, stainless steel construction. Designed and made in Canada.

-

High Quality Polyurethane Wipe Down Rollers

Many tape heads are fitted with separate roller sleeves, requiring frequent replacements due to surface breaks and splits. The result is tougher, longer lasting rollers requiring less maintenance.

-

Safe Operation

Independently mounted knife guard and actuator lever to minimize exposure of knife guard for greater operator safety.

-

Simply Dependable Performance

Single main wipe down spring for reliable, repeatable performance with easy and quick maintenance.

-

Tape Width

2" or 3"

-

Tab Length

2.325" - 2.75" (additional lengths available)

-

Speed

80 to 120 feet per minute

-

Tape Roll Size

1500 - 2000 yards

-

Construction

Corrosion resistant stainless steel

-

Country of Manufacturing

Designed and built in Canada

-

Mirror Image

Ideal for machine configurations that require access to tape head from opposite side.

-

Tape Monitoring

coming soon