ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more-

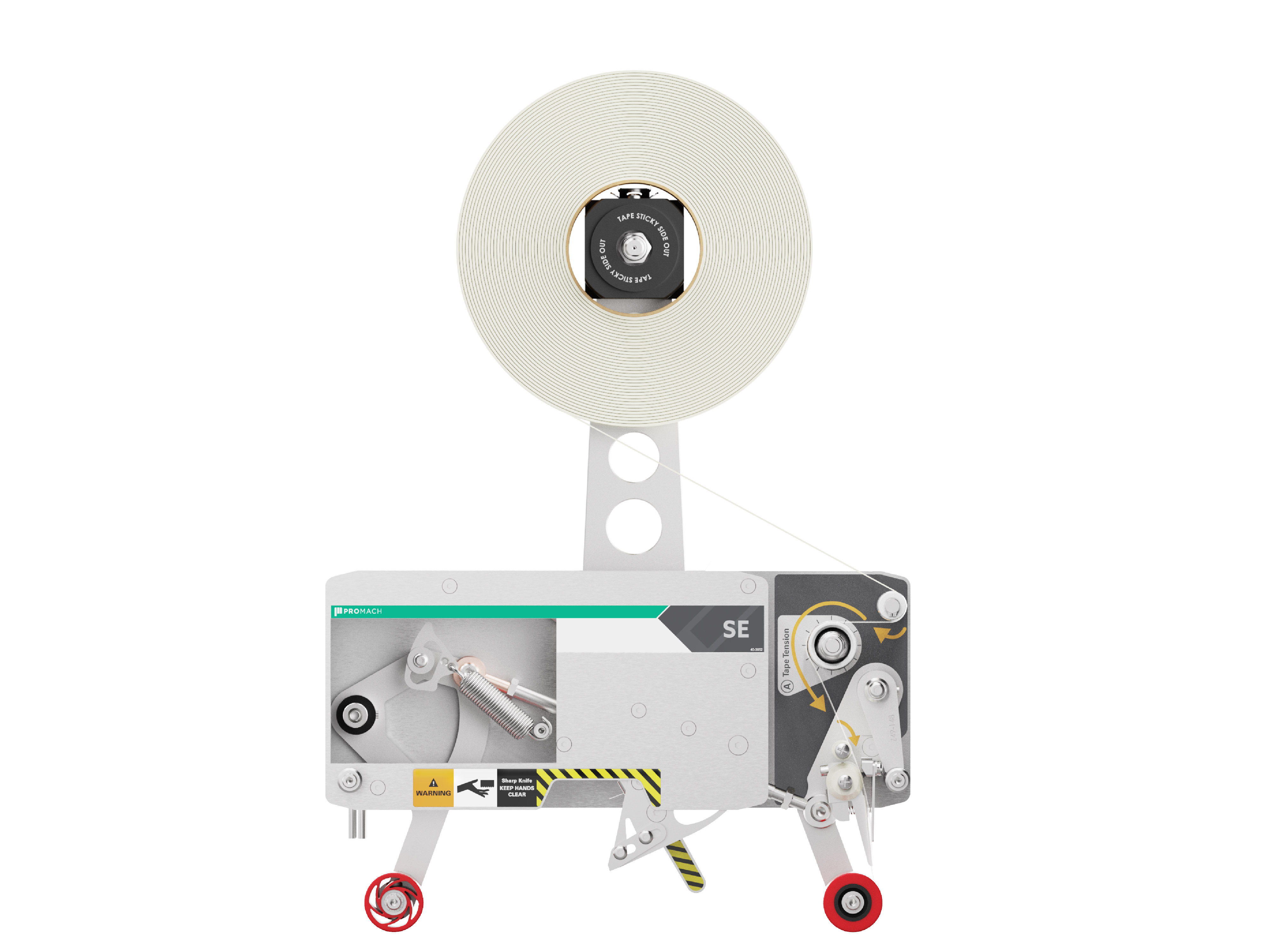

Soft Touch Feature

Second stage spring system allows for lesser collapse tension with a very rear wipe down to ensure the entire case is perfectly wiped down.

-

Smaller Application and Wipedown Rollers

Roller size is reduced to increase the speed of application

-

Shorter Cutter Lever

Lever length is adapted for faster cutting speeds

-

Patented No-Break Tape Advance

Advances the tape along its centerline to avoid edge stress and prevents tape breakage, eliminating delays and lost production

-

External Tape Guide System

Physically holds tape ends in place unaffected by external drafts or loss of static attraction to the wipe down roller

-

Adjustable Roller Tensions Spring

Main spring tension may be adjusted by selecting one of four preset leverage points. Adjustments are unaffected by vibration and shock

-

High Quality Molded Wipe Down Rollers

Polyurethane wipe down rollers are molded in one piece for tougher, long-lasting rollers that require less maintenance

-

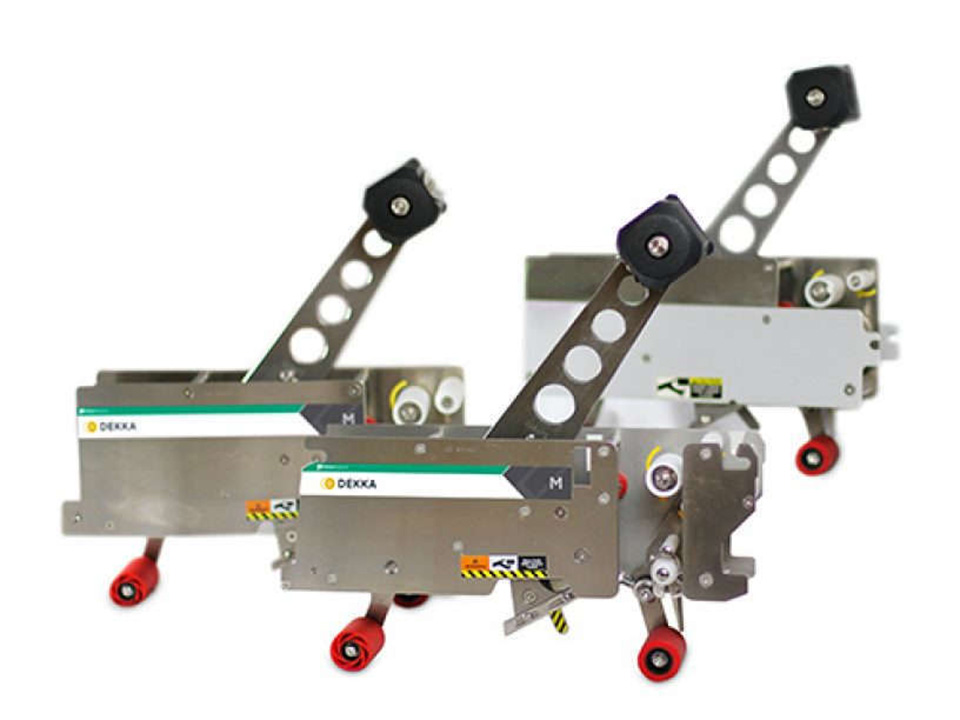

Quality Construction

High quality corrosion resistant, stainless steel construction. Designed and made in Canada

-

Tape Width

2" or 3"

-

Tab Length

2.125" - 2.5"

-

Speed

120 to 200 feet per minute

-

Construction

Corrosion resistant stainless steel

-

Country of Manufacturing

Designed and built in Canada

-

Mirror Image

Ideal for machine configurations that require access to tape head from opposite side

-

Mount

Horizontal Mounting version

-

Tape Management System

Designed to alert for low tape or broken tape